Hearing a high-pitched whistling sound while vacuuming can be frustrating and alarming. While it might seem like a minor annoyance, this noise often signals airflow problems, leaks, or worn components that compromise suction and overall performance. Ignoring the sound can result in greater wear on the motor, belts, or brush rolls, potentially leading to costly repairs.

Here, we will explore the main reasons vacuums whistle, provide step-by-step solutions for fixing the issue, and share maintenance tips to prevent the problem from returning. By following these strategies, you can restore quiet, efficient operation and protect your vacuum for the long term.

Why Is Your Vacuum Making a Whistling Sound?

A whistling vacuum is often more than just a noisy machine; it is a warning that something is interfering with the airflow. Vacuums rely on a precise path of air traveling from the floor through the hose, filters, and motor. Any obstruction, leak, or misalignment can accelerate the air in certain areas, creating the high-pitched whistling sound. Even a minor crack in a hose or a poorly seated canister lid can amplify the noise.

Similarly, dirt or hair caught in the brush roll or partially clogged filters can distort airflow, causing the vacuum to whistle. Understanding these mechanisms is the first step to identifying the exact source of the problem and resolving it effectively.

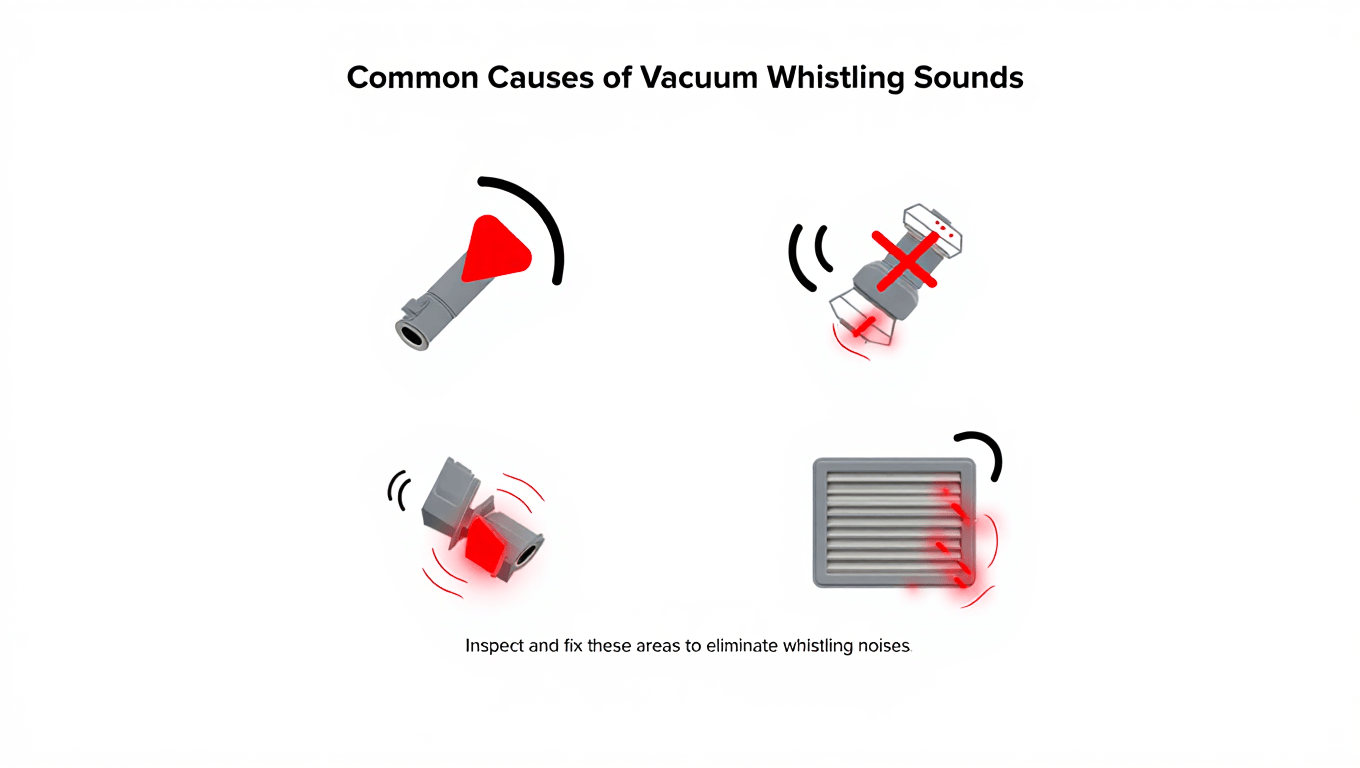

Common Causes of Whistling

Whistling is typically caused by issues related to airflow or friction within the vacuum. Air leaks in hoses, seals, or the dust canister are a frequent culprit, as escaping air creates the sharp, high-pitched noise. Dirty or misaligned filters are another common cause; when filters are clogged with fine dust or debris, the vacuum motor works harder, forcing air through restricted pathways, which generates the whistling sound.

Worn brush rolls or belts can also contribute by increasing friction and interfering with proper airflow. Blockages in attachments or suction pathways, even minor ones, can produce a whistling sound by forcing air through narrower passages than intended.

A practical example involves a pet owner whose vacuum began whistling after months of hair accumulation. Upon inspection, the hose had developed a small crack, and the brush roll was wrapped in long pet hair. After replacing the damaged hose and thoroughly cleaning the brush roll, the vacuum returned to normal, quiet operation. This highlights how a combination of airflow obstruction and minor component wear can create a pronounced whistling sound.

How Airflow Issues Create Whistling?

The whistling noise is largely a product of changes in airflow velocity. As air moves through the vacuum, it requires a smooth and unobstructed path. Any gap, crack, or partially clogged filter accelerates the air in localized areas, creating the sharp noise we recognize as whistling. High suction zones, such as small cracks in the hose or a slightly misaligned canister lid, can amplify the sound, turning a minor issue into a disruptive noise.

Additionally, restricted airflow forces the motor to work harder, increasing pressure inside the vacuum and exacerbating the whistling. In essence, the noise is a combination of high-speed air movement through restricted pathways and mechanical strain.

Signs That the Noise Indicates a Problem

Not all whistling noises are harmless, and recognizing warning signs can prevent further damage. A sudden increase in noise during normal operation often signals a new blockage or an air leak. If suction becomes uneven or weaker, it may indicate that the airflow is partially obstructed or that the motor is straining. Whistling accompanied by burning or rubber-like smells is especially concerning, as it may indicate motor strain or belt wear.

Persistent whistling that does not improve after basic cleaning is another red flag, suggesting that one or more components need thorough inspection or replacement. Recognizing these signs early allows for timely intervention and protects your vacuum’s motor and other critical components.

Step-by-Step Guide to Fix a Whistling Vacuum

Fixing a whistling vacuum requires a systematic approach to inspecting airflow, cleaning components, and addressing worn or misaligned parts. The first step is safety. Always unplug the vacuum before beginning any inspection or maintenance.

If the vacuum has been running, allow it to cool for at least 30 minutes to prevent burns or electrical hazards. Gloves and a dust mask are recommended to avoid contact with dust, debris, and allergens.

The next step is inspecting the filters. Filters are often the root of airflow-related whistling. HEPA filters, designed to trap fine dust and allergens, can become clogged quickly, particularly in homes with pets. Washable filters should be rinsed under cold water and dried completely before reinserting, while non-washable filters can be gently tapped to remove accumulated dust.

Ensuring the filter is properly seated is critical, as misalignment can create small gaps that amplify whistling. Investing in high-quality OEM filters is advisable, as aftermarket filters may slightly reduce airflow and increase noise in sensitive vacuums.

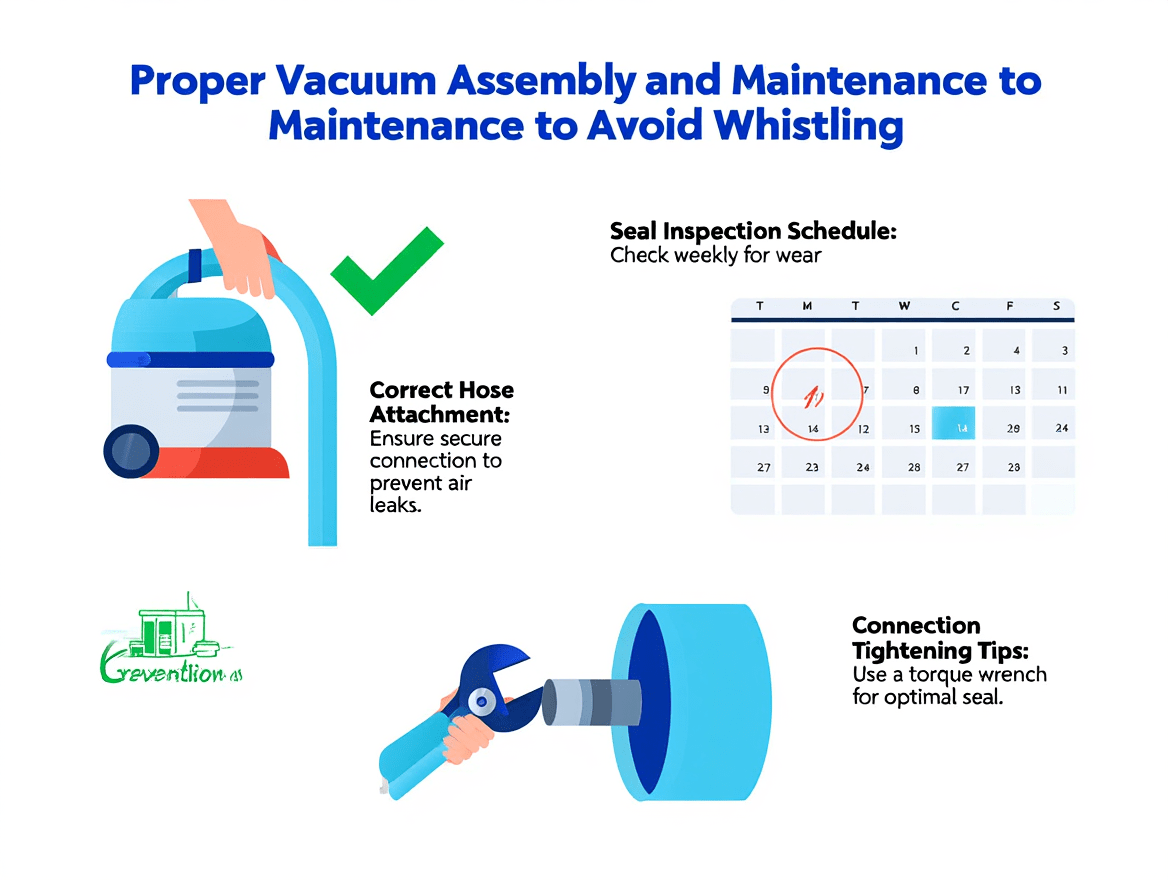

After filters, focus on hoses, seals, and attachments. Air leaks in any part of the vacuum disrupt airflow and create whistling. Inspect the hose for cracks or holes, ensure the dust canister lid is tightly sealed, and check that attachments fit securely.

Even a minor misalignment can produce noise, while a small crack in the hose can be patched or, if necessary, replaced. Cleaning internal pathways and attachments to remove dust and hair ensures smooth airflow and eliminates one of the most common causes of whistling.

Finally, inspect the brush rolls and belts. Hair, threads, or accumulated debris wrapped around the brush roll can distort rotation and interfere with airflow, generating noise. Ensure the brush roll spins freely and is properly aligned.

Worn or stretched belts create additional friction and should be replaced promptly. If the whistling persists after cleaning and inspecting these areas, consider using compressed air to remove dust from internal channels or consulting a professional to inspect the motor and internal seals.

Preventing Whistling Sounds in the Future

Establishing a Regular Maintenance Routine

Most vacuum whistling problems begin with neglect. When filters clog, hoses collect hidden debris, and brush rolls tangle with hair, airflow becomes restricted. Over time, this restriction builds pressure, and the high-pitched whistling begins.

Establishing a regular cleaning routine is the simplest way to prevent these noises from returning. For bagless vacuums, emptying the dust canister after every major cleaning session ensures dust does not pile up and block airflow. Bagged vacuums, on the other hand, require more attention to fullness indicators, as pushing a vacuum with an overfilled bag not only reduces suction but also stresses seals, making them more prone to letting out air at sharp, noisy pitches.

Filters also deserve scheduled care. Washable filters should be rinsed and dried completely at least once a month, while replaceable HEPA filters should be changed every six to twelve months, depending on usage. By following this routine, homeowners can preserve steady airflow and silence most potential whistling issues before they start.

Storage Practices That Protect Your Vacuum

Another overlooked factor is where and how the vacuum is stored. A vacuum kept in damp basements, garages, or laundry areas is more likely to suffer from weakened hoses and seals. Moisture softens rubber gaskets, causing them to warp or shrink, which leads to tiny air leaks that generate whistling noises. Dusty storage areas can also introduce extra dirt into the motor housing, making the unit work harder and increasing the chance of airflow disturbances. Storing the vacuum in a clean, dry, and upright position prolongs its life and keeps critical seals intact.

Even something as small as wrapping the cord properly helps. When cords are wound tightly around the body, they can pinch hoses or press against seals in awkward ways, stressing plastic joints. These tiny shifts might seem harmless, but over months of repetition, they create gaps that allow air to escape with a whistle. Good storage habits keep both performance and sound quality stable.

Using the Right Accessories for Cleaner Airflow

The attachments you choose also affect how your vacuum handles airflow. Using non-OEM or ill-fitting aftermarket parts can introduce gaps between the hose and wand or between the wand and the head. These small mismatches become channels for whistling. On the other hand, using well-fitting attachments that are designed for your specific model ensures smooth suction with minimal resistance. Pet hair tools, upholstery brushes, and crevice attachments should all fit snugly without wobbling or air gaps.

Some modern vacuums now come with self-sealing bags or advanced filtration systems that block dust from escaping. Investing in these parts is not just about reducing odors and allergens—it also stabilizes airflow, which is the biggest factor behind whistling sounds. If you often vacuum high-dust areas, such as workshops or garages, upgrading to these better accessories can save you from hearing that sharp whistle every time the vacuum runs.

Cost, Lifespan, and Replacement Considerations

When Cleaning Isn’t Enough

Even with regular maintenance, there comes a point where cleaning alone cannot silence a whistling vacuum. Motors eventually wear down, belts stretch, and seals dry out. If the vacuum is more than seven to ten years old, the whistling could be a sign that the internal motor is struggling to maintain suction. A failing motor often produces a mix of noises—not only whistling but also grinding or buzzing—that indicate serious wear. In these cases, replacing filters or cleaning hoses will not solve the issue, and it may be more cost-effective to replace the vacuum entirely.

The Cost of Replacement Parts

Homeowners often debate whether it’s worth repairing or replacing. The good news is that many common causes of vacuum whistling—like clogged filters, cracked hoses, or worn belts—are relatively inexpensive to fix. Standard vacuum filters range from $10 to $30, while HEPA filters cost closer to $40 or more. Replacement belts are usually under $15, making them one of the most budget-friendly fixes. Hoses, however, can range from $20 to $70 depending on the brand, and if the motor itself needs replacement, the repair could exceed $150, which is often more than half the price of a new unit.

Choosing between OEM and aftermarket parts also impacts cost. OEM (Original Equipment Manufacturer) parts guarantee a proper fit and often last longer, while aftermarket parts are cheaper but may not align perfectly, potentially reintroducing air gaps that cause whistling. For critical airflow components such as filters and hoses, OEM parts are usually worth the investment.

Vacuum Lifespan and Long-Term Value

A well-maintained vacuum should last between eight and twelve years, but only if it receives consistent care. Whistling is often an early warning that seals or filters are failing, and addressing it quickly prevents larger failures. If a vacuum is still relatively new, fixing a whistling sound with replacement filters or hoses is a wise investment. But for older units nearing the end of their lifespan, constant repairs may add up to the price of a new vacuum.

When buying a new model, it’s smart to consider designs that minimize noise and resist airflow issues. Look for vacuums with cyclonic suction technology, sealed HEPA systems, and self-sealing dust bags. These features not only improve performance but also reduce the chances of hearing that familiar high-pitched whistle as the machine ages.

Common Mistakes to Avoid

Ignoring Filter Replacement

One of the biggest mistakes homeowners make is neglecting filter replacement. Even if the vacuum seems to pick up dirt effectively, a clogged filter creates pressure inside the machine that has nowhere to go. The result is a sharp whistling noise as air forces its way through tiny gaps or around seals. Waiting too long to replace filters shortens motor life and makes whistling a recurring issue.

Vacuuming Wet or Sticky Debris

Many vacuums are not designed to handle wet debris. When moisture enters hoses or dust canisters, it mixes with dust and creates a dense blockage. Not only does this lead to foul odors, but it also restricts airflow, which intensifies whistling. Sticky substances, such as food crumbs with grease, can cling to internal walls and act as semi-permanent obstructions. Over time, these materials harden and force the vacuum to work harder, producing louder sounds.

Using Harsh Cleaning Solutions

Some users attempt to clean their vacuums with vinegar, bleach, or other strong cleaning solutions. While these might disinfect surfaces, they can also degrade rubber seals and gaskets, creating gaps that whistle under suction. A mild detergent and warm water are usually sufficient for cleaning canisters and washable filters. Sticking with the manufacturer’s recommended methods ensures longevity and keeps the vacuum quiet.

Storing Without Emptying the Canister or Bag

Leaving dust inside a vacuum between uses is another mistake that encourages whistling. As the debris sits, it compacts and sometimes clogs the exhaust path. When the vacuum is turned on again, air struggles to pass through, and the whistling begins immediately. Emptying the canister or replacing the bag after each major use prevents this problem and keeps performance consistent.

Conclusion

Fixing a vacuum that whistles is not just about comfort—it’s about protecting the motor, improving suction, and extending the machine’s life. By cleaning filters, maintaining hoses, using proper parts, and following preventive storage practices, you can keep your vacuum running smoothly for years. If your vacuum continues to whistle despite maintenance, it may be time to consider replacement parts or even a new model. Don’t wait for a small noise to turn into a major failure—start with maintenance today and enjoy quieter, more efficient cleaning.

FAQs

Why does my vacuum whistle even after cleaning?

If your vacuum still whistles after cleaning, the issue may be with worn-out seals or a cracked hose. Even small gaps can cause air to escape at high speed, creating the whistling sound. Replacing these parts usually resolves the issue.

How often should I replace vacuum filters?

Most manufacturers recommend replacing filters every 6–12 months, though washable filters should be rinsed monthly. Homes with pets or heavy dust require more frequent replacements to maintain airflow and silence whistling.

Can a vacuum motor cause whistling?

Yes. If the motor is failing, it may produce both whistling and grinding sounds. This usually means the bearings or internal fans are wearing out. At that point, motor replacement or buying a new vacuum is the only long-term solution.

Is aftermarket equipment okay to use?

Aftermarket parts can save money, but they often do not seal as tightly as OEM parts. This small difference may reintroduce airflow leaks that produce whistling. For hoses, filters, and seals, OEM is generally the safer choice.

How long should a vacuum last before noise becomes a problem?

With proper care, vacuums last 8–12 years before major issues arise. Whistling usually appears earlier, around the five-year mark, as seals and filters begin to wear. Addressing problems quickly prevents them from escalating into costly repairs.