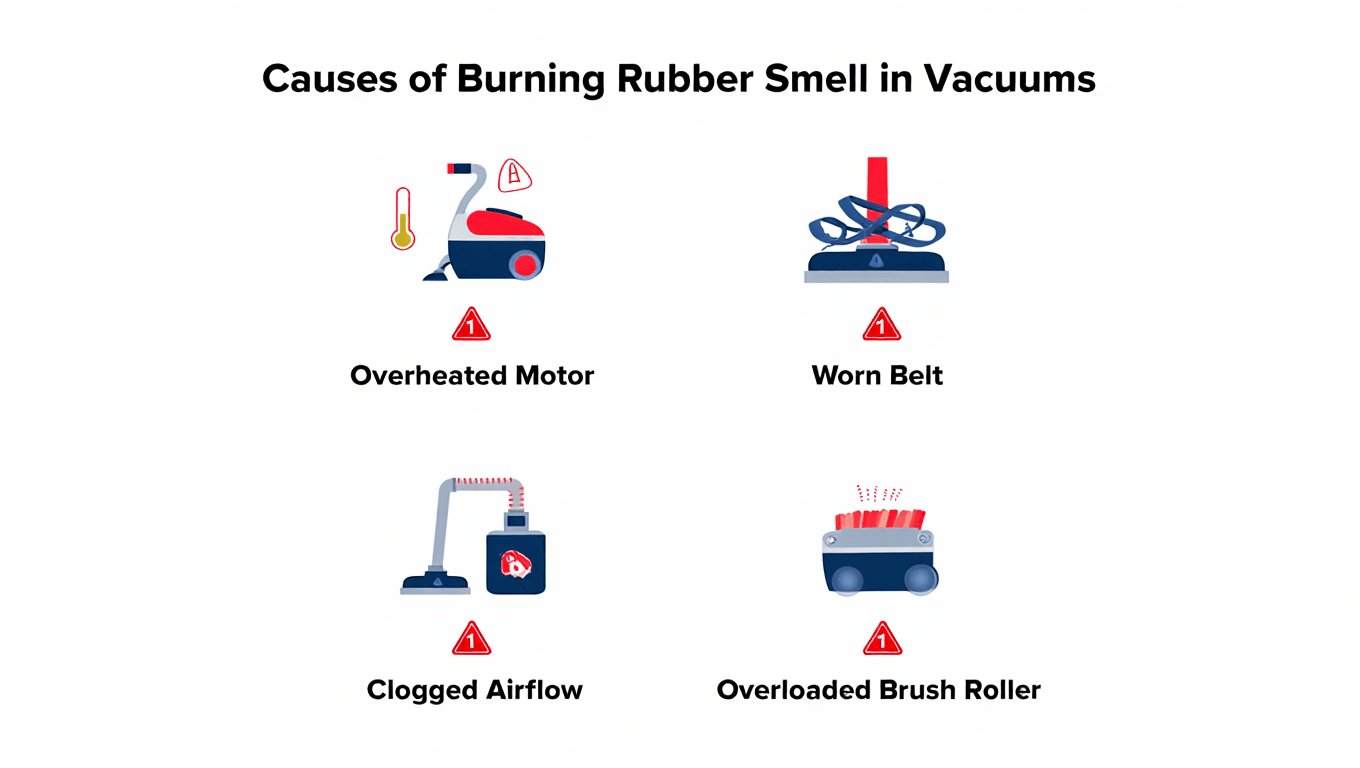

A vacuum that suddenly smells like burning rubber is a clear warning that something is wrong. This odor can indicate friction, overheating, or worn components that may damage your vacuum or create safety hazards. Many homeowners ignore the smell, assuming it’s normal, but addressing it promptly can prevent costly repairs and extend your vacuum’s lifespan.

In this guide, I’ll cover six common causes, from slipping belts to clogged filters, explain how to troubleshoot each problem, provide maintenance tips, and highlight the difference between OEM and aftermarket parts. Following these steps ensures your vacuum runs safely and efficiently.

1. Worn or Slipping Belts

The belt in your vacuum connects the motor to the brush roll. Over time, belts stretch, crack, or glaze, causing friction and producing a burning rubber smell. A slipping belt reduces brush roll efficiency, forcing the motor to work harder.

Example:

A homeowner using a high-pile carpet vacuum noticed a strong rubbery smell after only a few minutes of cleaning. On inspection, the brush roll belt was visibly frayed and slipping. Replacing the belt with an OEM part immediately stopped the odor and restored normal vacuum function.

Maintenance Tips:

- Check belts monthly for signs of wear, cracking, or fraying.

- Always replace with OEM belts for proper fit and durability; cheap aftermarket belts may wear faster or damage the brush roll.

- Keep a spare belt on hand for quick replacement, especially in households with pets or high traffic.

Cost-Saving Advice:

Replacing a $15–$25 belt is much cheaper than repairing a motor burned out from prolonged belt slippage. Regular inspection can prevent this issue entirely.

2. Overheating Motor

Vacuum motors generate heat during operation. If airflow is restricted due to clogged filters, full dustbins, or debris in the brush roll, the motor works harder, overheating and producing a burning rubber smell. Overheating can also shorten motor life and increase energy consumption.

Example:

A stick vacuum started emitting a rubbery odor when used continuously on a thick rug for 30 minutes. The homeowner noticed reduced suction. After cleaning the HEPA filter and emptying the dustbin, the smell disappeared, and suction returned to normal.

Maintenance Tips:

- Empty dustbins frequently to maintain airflow.

- Clean or replace filters as recommended by the manufacturer. OEM filters ensure proper airflow, while cheap aftermarket filters may restrict air and increase overheating risk.

- Avoid prolonged use on high-suction settings. Give the motor breaks during long cleaning sessions.

Cost-Saving Tip:

Regular maintenance reduces the likelihood of motor burnout, saving hundreds on repairs or replacement.

3. Jammed or Overloaded Brush Roll

The brush roll spins to agitate carpets and collect dirt. If it’s jammed with hair, threads, or small debris, the belt and motor strain to turn it, producing a burning rubber smell. This is common in homes with pets or thick carpets.

Example:

A family vacuum started emitting a strong odor on a shag rug. Upon inspection, hair had wrapped tightly around the brush roll. Cleaning the brush and replacing a slightly worn belt immediately resolved the problem.

Maintenance Tips:

- Remove hair and fibers from brush rolls monthly.

- Check the belt for wear or slipping. Replace OEM belts as necessary.

- Avoid overloading the vacuum with large debris or heavy items.

Cost-Saving Advice:

Regularly cleaning the brush roll prevents friction-related damage, extends belt life, and reduces stress on the motor.

4. Clogged Airflow or Filters

Restricted airflow forces the motor to work harder, producing heat and the burning rubber smell. Dust, pet hair, and debris can block hoses or filters, significantly reducing suction.

Example:

A canister vacuum began smelling after several months of use. The HEPA filter was completely clogged with fine dust. Cleaning and reinstalling the filter eliminated the odor, and suction returned to normal.

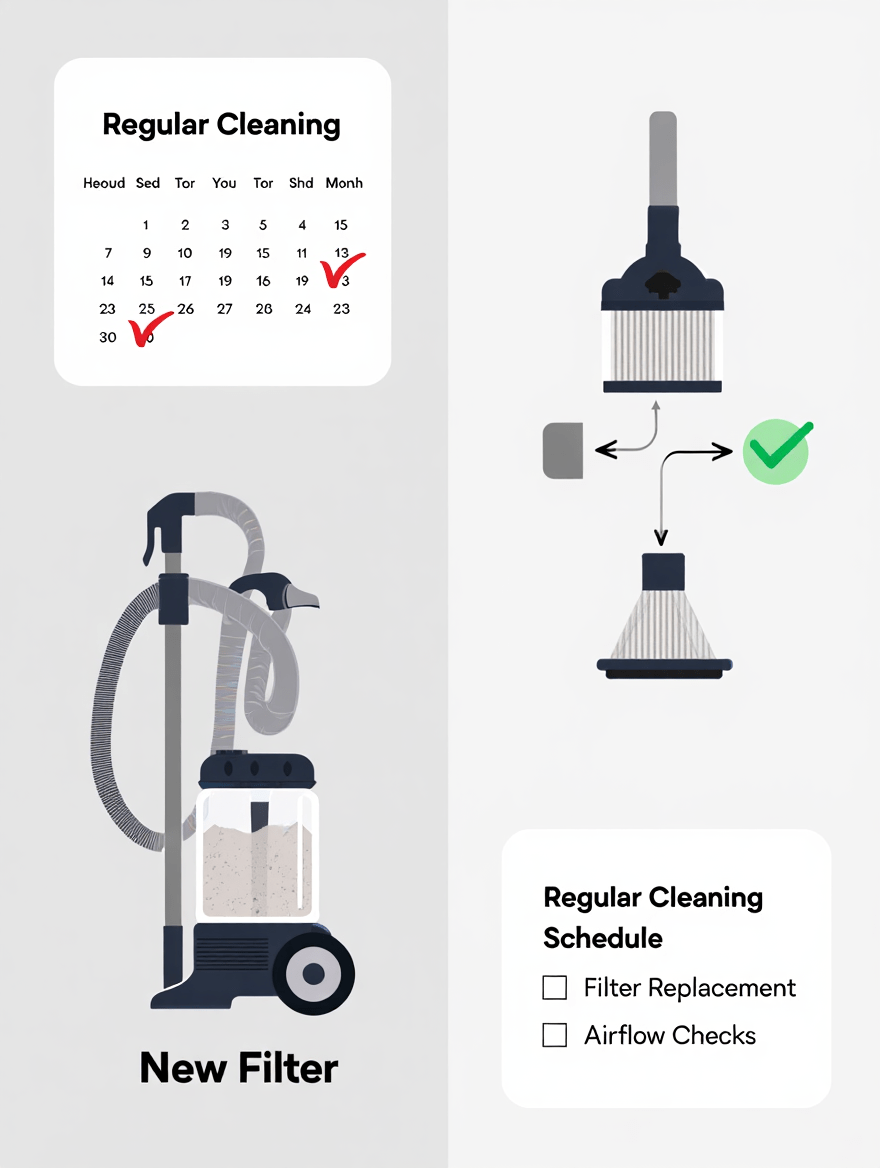

Maintenance Tips:

- Check and clean filters monthly, more often if you have pets.

- Wash reusable filters and replace non-washable ones as recommended.

- Inspect hoses and attachments for blockages.

OEM vs. Aftermarket Advice:

OEM filters are engineered for proper airflow. Many aftermarket filters may fit but restrict airflow, causing overheating and odor.

Cost-Saving Tip:

Investing in OEM filters prevents premature motor failure and maintains vacuum efficiency.

5. Worn Wheels or Plastic Components

Vacuum wheels and plastic parts can wear over time. Rubber wheels rubbing against axles or plastic housing generate friction, sometimes producing a burning rubber smell. This is especially common with vacuums used frequently on hard floors.

Example:

A stick vacuum emitted a smell while rolling across hardwood floors. Inspecting the rear wheels revealed slight melting and friction against the vacuum body. Replacing the wheels with OEM parts restored smooth operation and eliminated the odor.

Maintenance Tips:

- Inspect wheels monthly for cracks, flattening, or friction points.

- Replace worn wheels promptly to avoid damaging other components.

- Lubricate wheel axles with manufacturer-approved lubricants if necessary.

Cost-Saving Advice:

Regular wheel maintenance prevents friction-related damage to the motor and brush roll. OEM wheels ensure proper fit and longevity.

Advanced Causes of Burning Rubber Smell

If your vacuum continues to emit a burning rubber odor after checking belts, brush rolls, wheels, and filters, the issue may be more complex. Electrical components, overheating circuits, or misuse can also create this smell. Understanding these causes can prevent damage and extend your vacuum’s life.

6. Electrical Issues

Electrical faults, such as damaged wires, failing switches, or worn motor components, can produce a burning rubber or electrical odor. Sparks or overheating wiring may also pose a fire risk.

Example:

A homeowner noticed a rubbery smell from an upright vacuum shortly after turning it on. Upon inspection, a frayed wire inside the motor housing was overheating. Repairing the wiring and replacing the cover eliminated the odor.

Maintenance Tips:

- Inspect cords and connections regularly for fraying, cuts, or burn marks.

- Avoid running the vacuum with damaged wiring.

- Use OEM replacement parts for electrical repairs to ensure safety and proper fit.

Cost-Saving Advice:

Replacing frayed wires or switches early prevents complete motor failure, which could cost hundreds of dollars to repair.

Overheating Circuits or Motor Components

Even if belts and filters are fine, some vacuums can overheat due to prolonged use, blocked airflow, or defective motor components. Overheating triggers the burning smell and can reduce the vacuum’s lifespan.

Example:

A canister vacuum used for heavy debris over multiple rooms developed a burning smell. The motor had partially overheated. Allowing it to cool and cleaning airflow pathways fixed the problem temporarily, but repeated use highlighted the need for a motor inspection.

Maintenance Tips:

- Avoid running vacuums continuously for long periods on high-suction settings.

- Ensure all vents and filters are clean and unobstructed.

- If overheating persists, consult a professional for motor inspection.

OEM vs. Aftermarket Consideration:

OEM motors or replacement parts are designed for proper heat dissipation. Cheap aftermarket motors may overheat more easily.

Misuse or Improper Maintenance

Using the vacuum incorrectly—like attempting to pick up large debris, liquid, or high-heat materials—can cause belts to slip, motors to overheat, and components to emit a burning smell.

Example:

A homeowner used a standard upright vacuum to clean spilled pasta sauce. While vacuuming, the odor appeared as the belt and brush roll heated excessively. Immediate cleaning and drying of parts reduced damage.

Practical Tips:

- Only use the vacuum for its intended purpose.

- Avoid picking up liquids unless the vacuum is wet/dry rated.

- Perform monthly maintenance to remove hair, threads, and dust from all components.

Cost-Saving Advice:

Proper use and maintenance prevent premature wear, saving hundreds on replacement parts or a new vacuum.

Preventive Maintenance for a Smell-Free Vacuum

Regular preventive maintenance is the key to avoiding burning rubber smells. It keeps belts, brush rolls, wheels, and motors in top condition.

Cleaning and Inspection

- Remove hair and debris from brush rolls monthly.

- Inspect belts for fraying or slipping. Replace OEM belts promptly.

- Clean filters and dustbins regularly.

- Check hoses and nozzles for clogs.

Proper Use and Storage

- Do not overwork the vacuum on thick carpets or heavy debris.

- Store upright vacuums on flat surfaces to prevent wheel or axle damage.

- Keep vacuums away from heat sources and moisture.

Lubrication and OEM Components

- Lubricate wheel axles or brush roll bearings if recommended by the manufacturer.

- Use OEM parts for replacement to maintain proper fit, function, and durability.

Final Takeaway

A burning rubber smell from your vacuum is never normal. It typically signals worn belts, overheating motors, jammed brush rolls, clogged filters, friction from wheels, or electrical issues. Addressing the cause quickly prevents motor damage, costly repairs, and safety hazards. Regular maintenance—including cleaning brush rolls, replacing OEM belts, inspecting filters, and proper storage—ensures your vacuum runs efficiently and safely.

Use the vacuum according to manufacturer guidelines and replace worn parts promptly. Following these steps will not only eliminate the burning odor but also extend the life of your vacuum, keeping your home clean and your investment protected.

FAQs

Why does my vacuum smell like burning rubber when I turn it on?

This is usually caused by a slipping or worn belt, overheating motor, or debris in the brush roll. Inspect and maintain these parts promptly.

Can I keep using my vacuum if it smells?

No. Continuing to use a vacuum that emits burning smells can damage the motor or electrical components and may pose a fire risk.

How often should I replace belts?

Check belts monthly. Replace OEM belts as soon as you notice cracks, fraying, or glazing.

Do aftermarket parts work as well as OEM?

OEM parts are recommended for proper fit, durability, and safety. Cheap aftermarket parts may fail faster and cause overheating or odor.

Can clogged filters cause a burning smell?

Yes. Restricted airflow forces the motor to overwork, producing heat and the rubbery smell. Clean or replace filters regularly.

Can I prevent overheating?

Yes. Avoid prolonged use on high-suction settings, clean filters and hoses, and ensure brush rolls spin freely.

When should I call a professional?

If the odor persists after cleaning belts, brush rolls, filters, and wheels, or if you detect electrical issues, contact a professional technician immediately.